Iinkcukacha

Usetyenziso oluphambili lwepleyiti yentsimbi enganxitywayo kumazwe angaphandle:

1) Oomatshini bokwakha kunye nezixhobo: i-bulldozer excavator ipleyiti yebhakethi, ipleyiti esecaleni, ipleyiti esezantsi yebhakethi, iblade, ipleyiti.

2) Ukulayishwa kunye nokuthulula oomatshini kunye nezixhobo: ipleyiti yokuthulula ilitye lokusila, ipleyiti ye-hopper lining, ipleyiti yokubamba iblade, ubungakanani obuphakathi okuzenzekelayo bokulahla ipleyiti yokulahla ilori.

3) Oomatshini bokwakha kunye nezixhobo: ipleyiti yezinyo lesamente, ipleyiti yomxube wekhonkrithi, ipleyiti yokuxuba ephantsi, ipleyiti yokuqokelela uthuli.

4) Oomatshini besinyithi kunye nezixhobo: intsimbi ekrwada intsimbi ehambisa i-elbow, intsimbi yentsimbi yokucoca ipleyiti yentsimbi, ipleyiti yokucoca umatshini

5) Oomatshini bemigodi kunye nezixhobo: i-lining plate yoomatshini bokumbiwa kwemigodi.

6) Ezinye izixhobo zoomatshini: umgqomo wesanti, iblade, iindawo ezahlukeneyo zokunxiba ezinganyangekiyo koomatshini bezibuko.

7) Izixhobo zamandla obushushu: ibhodi yokusila yamalahle, i-coal scutcher, umbhobho wokuhambisa amalahle, ipleyiti yokuhambisa amalahle, ibhodi yokukhulula amalahle.

I-8) Ukudubula izixhobo zomatshini: i-lining plate yomatshini oqhumayo

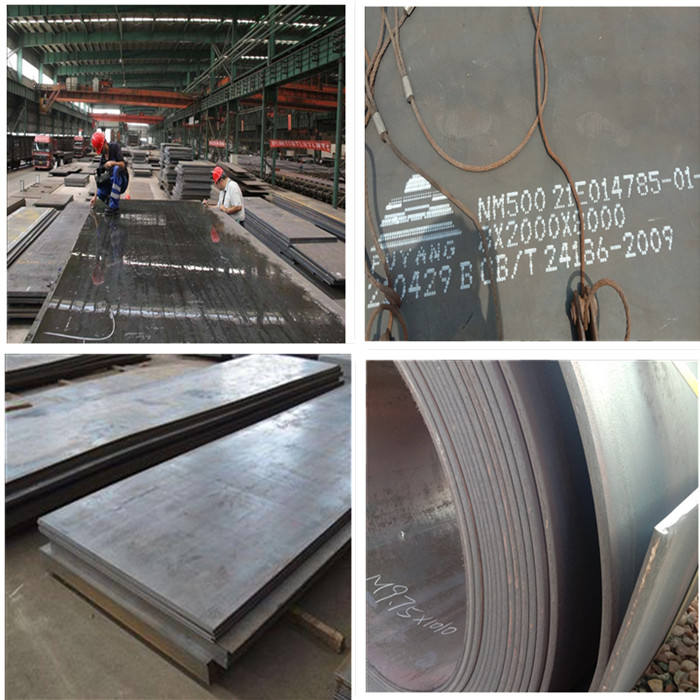

Ukusukela ekusekweni kwayo, inkampani iye kumgangatho weemveliso njengokusinda okusisiseko kweshishini, umgangatho wenkonzo njengebhulorho kwimpumelelo yethu sinethemba elinyanisekileyo lokuseka ubudlelwane beshishini kunye nabathengi bethu, ukubonelela ngenkonzo esemgangathweni, kunye noshishino, uphuhliso olufanayo.

Ngokuphuculwa okuqhubekayo, ukusungula izinto ezintsha, ukuze umgangatho weemveliso zethu zigcinwe kwindawo ephambili kwishishini lasekhaya.

Ithagethi yomgangatho: I-98% yeemveliso iphumelele ukuhlolwa kokunikezelwa kokuqala, i-0.2% yeemveliso ezingentla zigqithise ukunyuka kokuhlolwa kokunikezelwa kokuqala konyaka, i-100% yeemveliso idlula i-factory.

"Ingqibelelo, ukufuna inyaniso, uphuhliso, ukusungula izinto ezintsha" yinjongo yeshishini lenkampani yethu iminyaka emininzi, bamkele ngokufudumeleyo uninzi lwabasebenzisi bentsimbi engenasici kunye noogxa bethu ukuba bandwendwele inkampani yethu, ngenxa yesizathu sokunxiba ipleyiti eqaqambileyo.

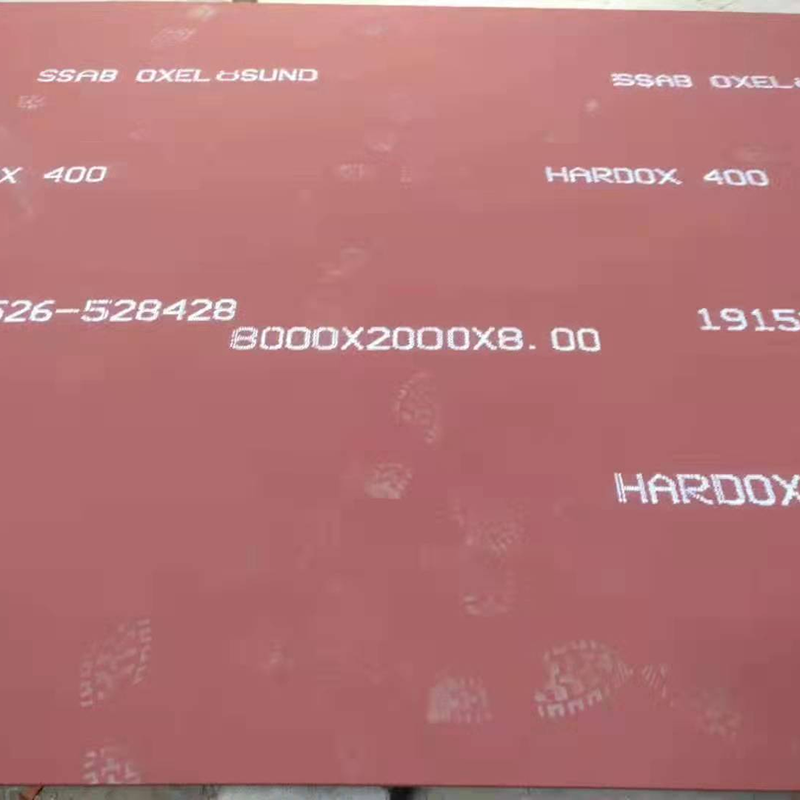

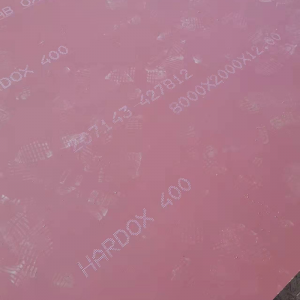

Ipleyiti yentsimbi enganxibiyo

| IBanga | NM360/NM400/NM450/NM500/RAEX400/RAEX450/RAEX500/NM360,BHNM400,BHNM450,BHNM500,BHNM550,BHNM600,BHNM650,NR4360,NR4360,NR4360,NR360,4 |

| Ukutyeba | 3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+6,8+7,8+8,10+4,10+ 5,10+6,10+7,10+8,10+9,10+10,10+20,12+4,12+5,12+6,12+7,12+8,12+9, 12+1,12+11,12+12, 12+17,14+6,14+8,14+10,16+6,16+8,16+10,18+6,18+8,18+10,20+5,20+6,20+ 8,20+10,20+20,30+10,40+10, ngokwezifiso |

| Ububanzi | 1500/2000/2500/3000MM |

Iimveliso ezingakumbi

1. Ukumelana nokunxiba okugqwesileyoUkubunjwa kweekhemikhali ze-alloy wear-resistant layer inomxholo wekhabhoni we-4 ukuya kwi-5% kunye nomxholo we-chromium we-25 ukuya kwi-30%.Iqhekeza levolumu ye-Cr7C3 carbides kwisakhiwo se-metallographic ingaphezulu kwe-50%.Ukuqina kwe-macroscopic yi-HRC56 ukuya kuma-62. Ukuqina yi-HV1400~1800. Ngenxa yokuba i-carbides ihanjiswa ngokuthe ngqo kwicala lokugqoka, nangona xa kuthelekiswa ne-alloys edibeneyo yokubunjwa okufanayo kunye nobunzima, ukuxhathisa ukunxiba kuphindwe kabini.Ukuthelekisa kunye nokuxhatshazwa kokugqoka kwezinto ezininzi eziqhelekileyo zilandelayo: (1) Ngensimbi ephantsi yekhabhoni;20~25:1 (2) Ngentsimbi etyhidiweyo yekhromium ephezulu;1.5~2.5:1

2. Ukumelana nempembelelo elungileyoIsiseko seplate yentsimbi edityanisiweyo yentsimbi iphantsi okanye i-alloy ephantsi.Izinto ezomeleleyo ezifana nentsimbi engenasici zibonisa ukongama kwebimetal.Uluhlu olungagungqiyo luchasa ukunxiba kwendlela yokunxiba, kwaye i-substrate ithwala umthwalo ophakathi, ngoko inokumelana nempembelelo entle.Iyakwazi ukumelana neempembelelo kunye nokunxitywa kwe-hopper ephezulu yokulahla kwindlela yokuhambisa izinto.

3. Ukumelana nobushushu obuhleUluhlu lwe-alloy-resistant layers luyacetyiswa ukuba lusetyenziswe phantsi kwe-≤600℃.Ukuba i-vanadium, i-molybdenum kunye nezinye i-alloys zongezwa kwi-alloy-resistant-resistant layer, inokumelana nokushisa okuphezulu kwe-≤800℃.Ukushisa okucetyiswayo okusebenzayo ngolu hlobo lulandelayo: Isiseko se-carbon steel esiqhelekileyo sinconywa ukuba sisetyenziswe phantsi kwemeko yokusebenza engekho ngaphezu kwe-380 ℃;Ipleyiti yensimbi ekwazi ukumelana nobushushu obuphantsi (15CrMo, 12Cr1MOV, njl.) i-substrates iyacetyiswa ukuba isetyenziswe kwiimeko zokusebenza ezingekho ngaphezulu kwe-540℃;I-substrate yensimbi engenasici ekwazi ukumelana nobushushu iyacetyiswa ukuba isetyenziswe kwi-800 ° C.

4. Ukumelana nokugqwesa okulungileyoUmaleko we-alloy weplate yentsimbi edityanisiweyo engagugiyo iqulethe ipesenti ephezulu ye-chromium yentsimbi, ngoko inomlinganiselo othile wokurusa kunye nokumelana nokugqwala.Ingasetyenziselwa ukuthintela ukunamathela kwamalahle xa isetyenziswa kwimigqomo yokulahla amalahle kunye neehopper.

5. Gqibezela iintlobo kunye neenkcukachaIpleyiti yensimbi engaguqukiyo ineenkcazo ezipheleleyo kunye neentlobo ezininzi, kwaye ibe yintengiso yokuthengisa.Ubukhulu boluhlu lwe-alloy ekwazi ukunxiba yi-3-20mm.Ubunzima beplate yensimbi edibeneyo ubuncinane ubuncinane be-6mm, kwaye ubukhulu abukhawulelwanga.Isitya esiqhelekileyo sensimbi esingaguqukiyo sinokubonelelwa nge-1200 okanye 3800 × 12000mm, kwaye sinokucutshungulwa ngokobukhulu bemizobo ngokweemfuno zomsebenzisi.Iipleyiti zetsimbi ezikwaziyo ukunxiba ngoku zihlulwe zibe ziindidi ezintathu: uhlobo oluqhelekileyo, uhlobo oluchasene nempembelelo kunye nobushushu obuphezulu.Ukuyalela i-high-temperature-resistant wear-resistant kunye nefuthe-resistant-resistant iipleyiti zentsimbi ezidibeneyo kufuneka zichazwe.

6. Ukusebenza ngokufanelekileyoIpleyiti yensimbi engaguqukiyo inokunqunyulwa, igobe okanye ikhutshiwe, idityaniswe kwaye ibethelwe, kwaye inokucutshungulwa kwiindawo ezahlukeneyo ezinokucutshungulwa ngamacwecwe ensimbi aqhelekileyo.Iipleyiti zentsimbi ezisikiweyo ezingagungqiyo zinokudityaniswa ngokwe-welded kwiindawo ezahlukeneyo zobunjineli okanye iinxalenye zobunjineli.

7. Imisebenzi kunye neempawuIyakwazi ukudityaniswa kwaye inokumelana nokunxiba kakuhle..